Come scegliere una pressa piegatrice CNC?

Oct 22, 2025

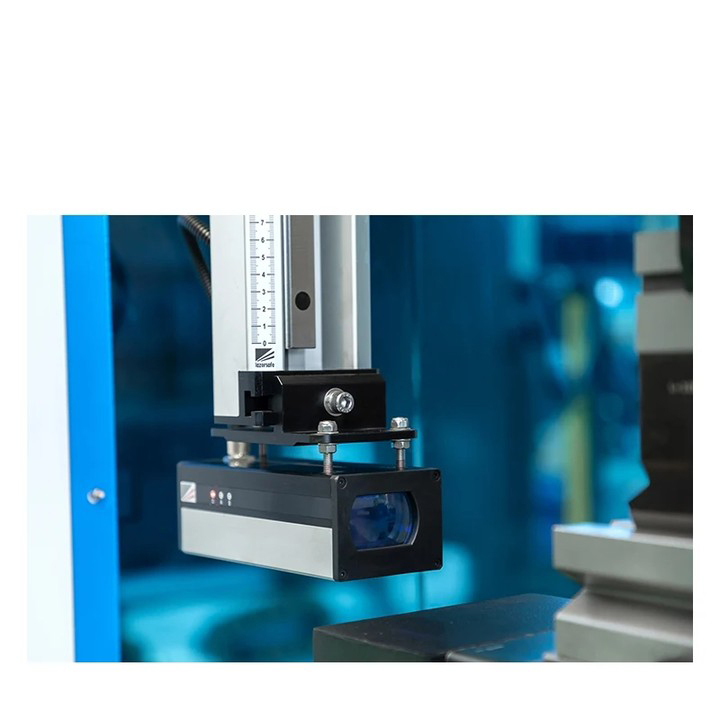

Scegliere il giusto pressa piegatrice CNC può fare una grande differenza in termini di efficienza produttiva, precisione di piegatura e redditività complessiva. Con così tante opzioni sul mercato, ognuna con caratteristiche, capacità di tonnellaggio e livelli di automazione diversi, è facile sentirsi sopraffatti. Questa guida ti aiuterà a capire cosa conta davvero nella scelta di una pressa piegatrice CNC, in modo da poter fare un investimento intelligente che si adatti alle esigenze della tua azienda. I. Considerazioni fondamentali (base per la selezione)1. Analisi dei requisiti di elaborazione (prima poniti la domanda)Proprietà dei materialiMateriale: si tratta principalmente di acciaio a basso tenore di carbonio, acciaio inossidabile, alluminio, rame, ecc.? La resistenza alla trazione dei diversi materiali varia, il che influisce sul calcolo del tonnellaggio.Spessore della lamiera: qual è l'intervallo di spessore delle lamiere che pieghi più frequentemente? Ad esempio: 0,5 mm - 6 mmDimensioni del foglio: quali sono la lunghezza e la larghezza massime di lavorazione? Ad esempio: 3 m x 1,5 mRequisiti del processo del prodottoAngolo di piegatura: solitamente 90°. È necessario piegare angoli ottusi, acuti o forme complesse?Requisiti di precisione: quanto sono elevati i requisiti di tolleranza per angoli e dimensioni? (Ad esempio: ±0,5° o ±0,1 mmDimensione del lotto di produzione: si tratta di un piccolo lotto con più varietà o di un grande lotto con un singolo prodotto? Questo dipende dalla richiesta di livello di automazione.Complessità delle parti: è necessario disporre di funzioni complesse come il movimento multiasse del fermo posteriore, l'avvolgimento e la pressatura del bordo morto? 2. Parametri chiave della macchina (a cui prestare attenzione durante la lettura del manuale dell'attrezzatura)Pressione nominale (tonnellaggio): questa è la capacità principale della piegatrice. Deve essere calcolata in base al materiale più spesso e duro.Formula di calcolo semplice: P = (650 * S² * L)/VP: Pressione richiesta (tonnellate)S: Spessore della piastra (mm)L: Lunghezza di piegatura (m)V: Larghezza della fessura inferiore della matrice (mm), solitamente pari a 8 volte lo spessore della piastra.Ad esempio, piegando una lamiera di acciaio a basso tenore di carbonio spessa 3 mm e lunga 3 metri utilizzando una matrice inferiore larga 24 mm, la pressione richiesta è di circa (650 * 3² * 3) / 24 ≈ 731 tonnellate. Pertanto, è più affidabile scegliere una macchina con una capacità di circa 100 tonnellate. Si consiglia di selezionare un tonnellaggio superiore del 20-30% rispetto al valore calcolato in caso di emergenza.Lunghezza del banco di lavoro: determina la lunghezza massima del foglio che può essere piegato. Selezionare in base alle dimensioni massime del prodotto. Le dimensioni più comuni includono 2,5 m, 3 m, 4 m, ecc.Profondità di gola: si riferisce alla profondità dalla linea di piegatura al lato interno del telaio. Determina se il lato piegato colpirà il corpo macchina durante la piegatura di pezzi di tipo "scatolato". Più profonda è l'apertura di gola, più ampio è il campo di lavorazione.Distanza tra le colonne: distanza tra i telai su entrambi i lati. La lamiera da piegare deve poter essere trasportata fino alla posizione di arresto posteriore attraverso questa distanza. Questo parametro è molto importante per la lavorazione di pezzi con pieghe al centro, come i "telai di porte di grandi dimensioni". 3. Sistema di controllo numerico e configurazione dell'automazione (determinazione dell'efficienza e della facilità d'uso)Marca del sistema di controllo numericoMarchi noti a livello internazionale, come Accurl, hanno sistemi stabili, funzioni potenti e una buona logica di funzionamento.Suggerimento per la selezione: scegliere in base ai costi di apprendimento e al budget dell'operatore. È importante considerare se l'interfaccia è intuitiva e la programmazione è pratica.Asse Y (controllo della corsa del cursore): l'asse centrale che controlla la profondità di piegatura (angolo). Di solito si tratta di un servosistema elettroidraulico. Il numero di assi Y determina se il cursore può rimanere parallelo in diverse posizioni. Per le macchine con piani di lavoro lunghi, sono necessari almeno due assi Y (uno per estremità) per garantire la precisione, e i modelli di fascia alta possono averne tre o più.Asse X (movimento avanti e indietro del fermo posteriore): controlla la posizione di piegatura. La corsa dell'asse X determina il margine minimo che può essere piegato. Il fermo posteriore dei modelli di fascia alta è suddiviso in più sezioni, il che può evitare i bordi già piegati.Asse R (arresto posteriore che si muove verso l'alto e verso il basso): viene utilizzato per evitare pezzi complessi o per realizzare processi speciali.Asse Z (movimento a sinistra e a destra del fermo posteriore): solitamente, la trave del fermo posteriore è divisa in due sezioni, sinistra e destra, che possono muoversi indipendentemente e vengono utilizzate per piegare pezzi smussati o asimmetrici.Selezione e abbinamento automatizzati (migliorando significativamente l'efficienza)Compensazione della flessione: quando la superficie lunga del tavolo viene piegata, il cursore e la superficie del tavolo subiranno una leggera deformazione dovuta alla forza, con conseguenti angoli intermedi imprecisi. La funzione di compensazione della flessione (idraulica o meccanica) può contrastare automaticamente questa deformazione ed è una configurazione chiave per garantire la precisione di piegatura di pezzi lunghi. Si consiglia vivamente di dotarsene.Cambio automatico dello stampo: per condizioni di lavoro in cui i cambi dello stampo sono frequenti, può far risparmiare notevolmente sui tempi di preparazione.Robot o carico e scarico automatici: adatti per produzioni ripetitive e su larga scala, realizzando officine "senza personale".Ii. Selezione del tipo di apparecchiaturaTipo con movimento verso l'alto (tipo con telaio ad arco): il cursore si muove verso il basso. Il tipo tradizionale presenta buona rigidità ed elevata precisione ed è adatto alla maggior parte degli scenari applicativi.Tipo di movimento verso il basso: il tavolo di lavoro si muove verso l'alto. Il corpo ha un baricentro basso, una buona stabilità e una superficie di appoggio ridotta, ma lo spazio operativo è relativamente angusto.Iii. Verifica in loco e servizio post-venditaTest campione: assicurati di portare i tuoi prodotti e le tue piastre tipiche (in particolare quelli più spessi, lunghi e impegnativi) al produttore o ai clienti esistenti per i test in loco.Controllare la precisione e la rettilineità dell'angolo di piegatura.Verificare la praticità di programmazione del sistema di controllo numerico.Sentire il rumore e le vibrazioni quando la macchina è in funzione.Verificare il servizio post-vendita: chiedere al produttore se sono presenti punti di assistenza nella vostra zona, quanto tempo impiegano per rispondere e se la fornitura di pezzi di ricambio è sufficiente. Un buon servizio post-vendita può ridurre notevolmente le perdite dovute ai tempi di fermo. se avete altre idee, contattateci!Tel: +86 -18855551088E-mail: Info@Accurl.comWhatsapp/Cellulare: +86 -18855551088